Specific Oxygen Uptake Rate: The

Fifteen Minute BOD

The goal of this article is:

1. To

introduce readers to the marvelous benefits of the Specific Oxygen Uptake Rate

Learn Theory! Learn Theory! Learn Theory! If you know

theory you can use it! If you don’t know theory you can’t use it!

Thinking

in terms of complex systems is difficult. Many people, even after studying for

years, do not understand basic principles. Systems thinking is often

counterintuitive at many points. It takes many years to gain any degree of

skill, and it still often eludes us. (Extraordinary Leadership:

Thinking Systems, Making a Difference, 2009, Reberta M. Gilbert, M.D, pg 5)

____________________________________________________________________________________

The Georgia Rural Water Association is

always available to assist any municipality that serve a population of

<10,000 with process control, troubleshooting, training, lift station

maintenance, smoke testing, leak detection, standard operating procedure

development, asset management development, or any other compliance and

operational issues that may crop up. To request their assistance, please

contact them at Contact Us -

Georgia Rural Water Association (grwa.org).

The next few

posts will focus on Activated Sludge Concepts. After that, I will focus

on some water related topics of interest.

************************************************************************************

Specific Oxygen Uptake Rate (SOUR)

The Most

Valuable yet underutilized test available for operators of the Activated

Sludge Process (University of Tennessee) [capitals and emphasis Dennis

Brown]

The SOUR calculates

the specific amount of oxygen utilized in a specific time period (usually

five minutes) by the specific amount of MLVSS in your system [Dennis’

definition] .

The BOD calculates the specific

amount of oxygen utilized in a specific time period (usually five days)

[Dennis’ definition].

“if you were being sent to an

island in the Pacific and was told you would only be allowed two process

control tests to take with you, what would you take?”

This is a question that has

floated around the wastewater industry for years. If you are like me, you

oscillate between tests depending on the day of the week or the specific issues

you are currently experiencing. One test would I take would definitely be the

settleometer test. It provides a wealth

of information in its own right, but even then I sometimes wonder if I would

not be better served with the centrifuge test? I can generally gauge the water

clarity by looking down in the clarifier. Determining the solids concentration,

however, is a different matter and the centrifuge would be a better test for

that purpose. But if I had a choice between the BOD and the SOUR test, it

would, hands down, be the SOUR test.

WHAT IS AN SOUR?

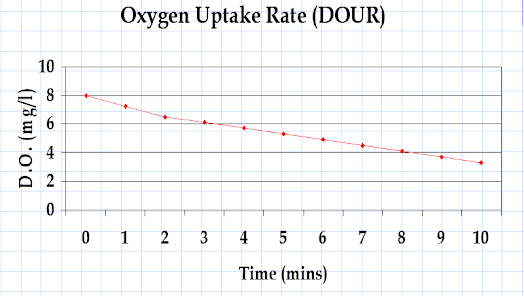

The basic SOUR test consists of

taking a sample of biosolids, aerating it vigorously for 1 – 2 minutes to

saturate the sample with oxygen, pouring the highly oxygenated MLSS into a BOD

bottle and taking DO readings with a DO meter over the next ten to fifteen

minutes. If plotted over time, it would look like figure 1a (after around 2

minutes for the excess oxygen to leave the bottle). Figure 1b illustrates OUR

tests at different F/M ratios.

FIGURE 1. Ten Minute Dissolved

Oxygen Profile

FIGURE 1b OUR at different F/M

ratios

The next step is to convert the

value to mg/L of DO per hour. So, for the ten (10) minute DO profile in figure

1 above, subtract the final reading from the initial reading and multiply it by

six (6). The final part of the equation would be to multiply that figure by

1000 then divide that figure by the MLSS or MLVSS if you prefer. The proper

equation is shown in FIGURE 2a. with an example in 2b.

FIGURE 2a Calculations for the

SOUR

FIGURE 2b Example

The practicality of effluent BOD

test is almost limited to demonstrating the plant meets compliance. As far as a

process control tool, by the time the results arrive the plant could already be

in a tailspin. The influent BOD is more practical in that it is used in the

Food/Microorganism Ratio calculation. But, like the Settleometer test, the SOUR

test can be used in many different ways in many different locations to provide

a wide range of information. For example, it can be used:

1.

to determine the amount of food entering the

biomass at any given time

2.

to determine the quality of food

3.

to detect the presence of and degree of toxicity

4.

to determine the health of the biomass

5. to

determine the degree of oxidation

Let’s take these in order.

TO

DETERMINE THE AMOUNT OF FOOD ENTERING THE BIOMASS

The SOUR

test lends itself to one very important characteristic. The sample can be

‘spiked’ with varying amounts of different substances to see what effect those

substances will have on the MLSS. A SOUR test run with MLSS alone under normal

operation will provide valuable information about the health of the organisms

and the degree of oxidation. If a portion of the sample is mixed with influent,

the increase in the oxygen uptake can tell the staff something about the amount

of food entering the system. In order for this to be valuable, several tests

would have to be run on samples with different ratios of Influent/MLSS (for

example, 1%, 2.5% and 5%). Plotted over a period of time, the SOUR’s, spiked

with the different ratios, should enable the staff to determine the relative

influent BOD concentration from the final SOUR values.

The

staff should also be able to determine how much food is entering the system at

any given time. Let’s say an egg cracking plant is known to discharge high

strength wastes on occasion. Unless the plant is equipped with a DO meter in

the aeration basin, the staff is unlikely to know something entered the plant

until they took an instantaneous DO reading with the field meter. Even then

they would not know the full extent of the damage. The SOUR could provide some

rapid feedback on how the plant was impacted. It would also provide valuable

feedback on the plant’s recovery – much faster than waiting for a 5-Day BOD

test.

Let’s

take this one step further and assume the plant has an equalization basin (EQ).

Yes, a luxury, but one that some plants do have. The plant could divert flow

from the aeration basin to the EQ basin, conducting a SOUR test on the MLSS,

spiking it with a portion of the influent to determine when the high-strength

BOD has passed.

Later,

when the influent returns to normal, the SOUR test could be spiked with the

high-strength waste from the EQ (blended with the influent at different ratios)

to determine how many gallons per day of the EQ waste can be returned back to

the head of the plant.

In

municipal systems with varying industrial waste streams, the SOUR can be used

to determine the relative strength of the influent at any given moment.

TO

DETERMINE THE QUALITY OF FOOD

Once

again, assuming a municipality that either receives flow from industrial plants,

receiving septic tank waste, leachate or receiving a discrete waste load from

any other location, the SOUR sample can be spiked with the unknown product to

determine the impact of discrete waste streams on the biomass. Some industries

may have discharges that are not consistent. An industry that produces

different products on different shifts, or may have an occasional discharge

that is significantly different from normal. The SOUR test can be used to

determine the impact on the biomass prior to discharge. It can also be used to

determine the amount of a specific substrate (technical name for ‘food’) that the

biomass is capable of assimilating.

TO

DETECT THE PRESENCE AND DEGREE OF TOXICITY

The SOUR

test can be used to detect the presence of toxic substances in discrete waste streams

or the influent. Here are two examples. Hopefully these may give you ideas for how

you may integrate the SOUR test in your facility.

Cyanide

in the Influent

I worked

at a facility (Facility B) that was downstream from another facility (Facility

A) run by the same municipality. Facility A had a plating shop that discharged

into its collection system. Late one evening the plating shop discharged a waste

stream containing excessive levels of cyanide that killed the biomass in

Facility A. The operation staff was alerted to an issue when they conducted one

of their normal DO tests (conducted once every 6 hours round the clock) and

noticed the DO was excessive, indicating no microbial activity. They suspected

something was wrong and called their Plant Manager (PM), who called the

Director. The director immediately had the staff close the influent gate to Facility

A which directed all their influent to Plant B. The director then called the PM

of plant B (me). I called my staff and, knowing it took about six hours for the

flow from Facility A to reach Facility B, called in an additional person and instructed

them to start running SOUR tests on the MLSS spiked with 5% influent. When the

DO of the SOUR started to flatline, the staff diverted the influent into our EQ

basin. This continued until the spiked SOUR test no longer indicated any inhibition.

Samples

from Plant A’s MLSS and the EQ basin at Plant B were sent to a local lab for

analysis. It was determined that both waste streams contained high levels of

cyanide. Once we know what the culprit was we could develop a plan of action.

In the

early 1980’s I had also worked in a plating shop where they used cyanide in the

plating process. I was the wastewater operator. In addition, I have a chemistry

degree and therefore knew some things about cyanide. It tends to gas off rapidly

at a neutral pH. Also, chlorine is used to ‘destroy’ cyanide in wastewater

plants. Therefore, all we had to due to neutralize the cyanide is either add

chlorine or wait.

Based on

the low levels of cyanide in the basins at both plants, it was decided we would

wait and let the cyanide gas off on its own. It took four days for the cyanide

to dissipate and we were able to bring the flow from the EQ back into the

plant. At the same time activated sludge was hauled from some of our other

facilities to reseed Plant A.

SEPTIC TANK DISCHARGES

I was working

as an operation specialist for a contract operation firm and visited a facility

in New England that serviced 15 – 20 septic tank trucks per day. On occasion a

septic truck would dump something that would have an adverse impact on the

plant. The procedure they put in place to manage it was to save a 250 mL sample

from every truck, which they saved for two days. If they had an adverse

reaction they suspected was from a septic truck, they would run an SOUR spiked

with 10% septic tank waste, beginning with the most recent sample and working

backwards. The culprit was then banned from dumping.

Another

way to approach the problem, it the plant only receives two to four trucks per

day, would be to conduct a SOUR with a small sample from the septic truck prior

to discharge.

TO

DETERMINE THE HEALTH OF THE BIOMASS

If a

SOUR is run on a sample taken at the same location and time of day it can tell

the staff a lot about the health of the biomass. Figure 3 offers typical SOUR

values for different type of activated sludge plants.

FIGURE

3

High SOUR biomasses will settle slowly, not

compact well and the effluent can be high in BOD, TSS, ammonia and phosphorous.

Very low

SOUR biomasses will settle fast, compact well and have noticeable pin floc.

TO

DETERMINE THE DEGREE OF OXIDATION

A sample

taken at the end of the aeration basin just before going to the clarifier can

let the staff know if the waste stream is sufficiently oxidized. A sufficiently

oxidized biomass will use little oxygen and indicated the effluent will be low

in BOD. If the SOUR uses more oxygen than normal, it may mean the plant is not

carrying enough solids, or has received a slug of high-strength waste.

If a

sample taken in the middle of the aeration basin is highly oxidized (the DO slope

is flat), it is an indication the plant is carrying too many solids. If the aeration

basin is not oxidized enough (the DO slope is steep) the plant needs to carry

more solids, or the hydraulic detention time needs to be increased.

Refer

back to figure 3 for typical values.

USING

THE SOUR AS A PROCESS CONTROL TOOL IN BNR PLANTS

Let’s

use the configuration in figure 4.

FIGURE

4. Typical BNR Plant

Carbon (food, BOD) is required in every part of the process. No matter what the configuration, the last tank will receive the least amount of BOD. This can have a negative impact on that specific process. If our example, the anoxic tank is last. It is possible, depending on the amount of phosphorous entering the anaerobic tank and the biomass concentration in the system that the anoxic tank might be BOD deficient.

The SOUR

test is the best method for determining if there is enough BOD in the system

for the completion of the denitrification process. However, the ideal SOUR

value will have to be determined by means of trial and error.

The spiked

SOUR test is also the best method for determining how much BOD needs to be

added to the system to complete the denitrification process. The specific

substrate (food) that will be used for the biomass to must be used in the SOUR.

Different ratios can be added to the SOUR to determine the ideal amount of

substrate to be added to the basin.

SUMMARY

Successful

Wastewater Treatment is all about optimizing the relationship between Food and

Population (F/M). This relationship has a direct effect on the respiration rate

of the Organisms. The SOUR Test takes advantages of these relationships to

provide almost instantaneous feedback to the operator. It can be used to

indicate toxicity, to determine the degree of oxidation of the treated waste,

as a titration method to determine how much of a waste stream a system can accept

or how much substrate to add for optimal treatment.

Feel free to contact me should

you serve a population >10,000 or have any questions or issues that the GRWA

is unable to assist you with. Also, if you would like to contribute an article

feel free to email me at the address below. I am always looking for

contributors that have an interesting perspective, topic or has an interesting

case that they would like to share – especially if the solution is a direct

result of applying the principles from this forum.

Dennis Brown,

Wastewater Specialist and Trainer, Retired

678.750.3996

Comments

Post a Comment