The Four Pillers of Activated Sludge

The goal of this article is:

- To Introduce the reader to the basic framework of activated sludge troubleshooting and process control.

- To provide basic guidance in using this basic framework in optimizing and troubleshooting the activated sludge

Learn Theory! Learn Theory! Learn Theory! If you know theory

you can use it! If you don’t know theory you can’t use it!

____________________________________________________________________________________

The Georgia Rural Water Association is

always available to assist any municipality that serve a population of

<10,000 with process control, troubleshooting, training, lift station

maintenance, smoke testing, leak detection, standard operating procedure

development, asset management development, or any other compliance and

operational issues that may crop up. To request their assistance, please contact

them at Contact Us - Georgia Rural Water Association

(grwa.org).

The

next few posts will focus on Activated Sludge Concepts. After that, I

will focus on some water related topics of interest.

***********************************************************************************

My career from April 2002 till

June 2023 involved many hours per week of windshield time and many lonely

nights in hotels. Interspersed in this time were numerous calls for assistance

in troubleshooting issues with activated sludge facilities. Early on, to get a

handle on the issues at the facility, I would either go to the plant to review

the data, or have the staff email me the data if it was in a suitable format. Being a ‘road warrior’ offered me plenty of

time for contemplation and meditation. The following Four Piller Framework came

to me one day during one of those contemplation sessions between plant visits.

I was mulling over how I could more effectively troubleshoot plant compliance

issues without having to visit the plant or request information to be emailed

to me when I realized wastewater could be boiled down to four basic themes: Food,

Population, Time and Environment.

Think of the Activated Sludge Process as a Table, and the four themes as the four legs.

|

|

|

FOOD can be subdivided

into: Quality (proteins, carbohydrates, fats, ammonia, phosphorous, nutrients);

Quantity (Too much, too little, just right?); Form (soluble, insoluble, etc)

and Inert (sand, silt, grit, wood chips, sawdust, etc).

POPULATION can be

subdivided into: Quality (floc size and shape, clarity of water between floc,

settleabilty [SVC, SVI], filamentous organisms present, etc); Quantity (MLSS, MLVSS,

settleabilty [SVC, SVI], relative population of Indicator Organisms, relative

population of filamentous organisms); also of importance is knowing the relative growth rates of various organisms (growth rates can vary from a few minutes to +40 days)

TIME can be subdivided

into: Hydraulic Detention Time (capacity issues [Flows too high/low affecting

treatment, settled solids taking up volume in reactors], Recycle/Recirculation [Flows

too high/low affecting retention time or settling]); Solids Retention time (F/M

Ratio, MCRT, SRT)

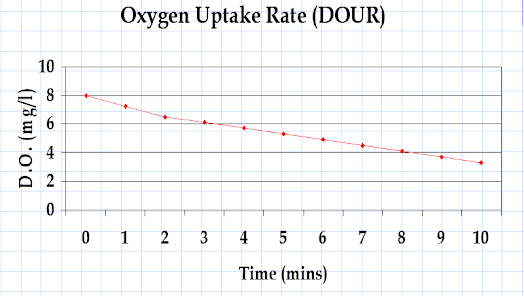

ENVIRONMENT can be

subdivided into: Dissolved Oxygen levels, Adequate Mixing, Alkalinity, pH, Temperature,

Oxidation/Reduction Principle (ORP), Toxicity, Surfactants, presence of

nitrates or oxygen in “anaerobic” zones (Q - When is an anaerobic zone really

an anoxic zone? A - When nitrates are present), presence of oxygen in an anoxic

zone.

The beauty of reducing activated

sludge down to four basic principles is the ability to ask pointed questions and

quickly drill down towards a solution. These principles enabled me to take a

phone call and troubleshoot a WWTP compliance issue within a relatively short

time just by asking a few specific questions. The ability to troubleshoot WWTP issues

on the phone was critical when traveling 40+ weeks out of the year.

But don't let the simplicity of the above overview fool you. Many of these subdivisions can be placed in two or more categories. For example, organism growth rates can be placed under the heading of population and time. F/M ratio can be placed under food, population and time. This just adds to the complexity, which is all the more reason for trying to simplify process control in the first place.

Someone might ask, ‘What about

mechanical issues? Won’t they have an impact on treatment? You don’t even

address these!’.

To the above question my answer

would be this. I cannot tell you how often ‘operation’ issues can be traced to

mechanical issues. If one is experiencing a dissolved oxygen (DO) issue, one should

inspect the mechanical equipment (Blowers: inspect the intake/outlet to see if

there are obstructions, the vanes to make sure they clearances are correct, the

piping to make sure there are no leaks, the motor, couplings and belts to make

sure there are no issues there. Brush Aerators: inspect the motor, couplings

and belts, inspect the water submergence. Impellor devises: Inspect the

impellors for wear, the shear pins, belts couplings, etc). Check the recycle/recirculation

pumps to make sure they are pumping the rated capacity. Etc.

Having the ability to rapidly

troubleshoot issues at your plant will enable you to focus more on the other

times that take up your time: personal, maintenance, regulatory issues, etc.

The next post will begin to introduce the subcomponents of the framework introduced above and provide more information on how to use them in process control and troubleshooting.

Feel free to contact me should

you serve a population >10,000 or have any questions or issues that the GRWA

is unable to assist you with. Also, if you would like to contribute an article

feel free to email me at the address below. I am always looking for

contributors that have an interesting perspective, topic or has an interesting

case that they would like to share – especially if the solution is a direct

result of applying the principles from this forum.

Dennis Brown,

Wastewater Specialist and Trainer, Retired

678.750.3996

Comments

Post a Comment