Basics of the Biological Nutrient Removal

Process

- To Introduce the reader to the basic framework of the Biological Nutrient Removal (BNR) Process.

- To provide basic guidance in using this basic framework in optimizing and troubleshooting BNR processes.

Learn Theory! Learn Theory!

Learn Theory! If you know theory you can use it! If you don’t know theory you

can’t use it!

Thinking in terms of complex

systems is difficult. Many people, even after studying for years, do not

understand basic principles. Systems thinking is often counterintuitive at many

points. It takes many years to gain any degree of skill, and it still often

eludes us. (Extraordinary Leadership: Thinking Systems, Making a

Difference, 2009, Reberta M. Gilbert, M.D, pg 5)

This article is not a primer or

refresher on nitrification, denitrification or phosphorous removal. It assumes

the reader already has a basic understanding of these processes. If you feel

you need a refresher, please refer to any of the Water Environment Federation’s

(WEF) Manual of Practices (MOP) for Wastewater. A copy of MOP 11 can be found

for free download on the internet. Key concepts crucial for understanding the

BNR process will be provided at specific places in the discussion.

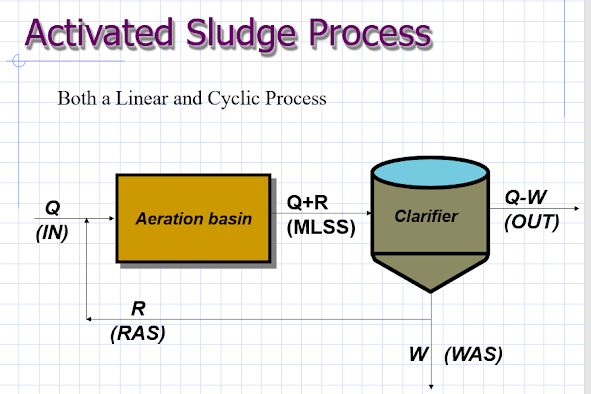

For example, it is important to

remember that the activated sludge is a cyclic process as well as linear one.

The fact that each tank has an influent and an effluent is a sufficient

reminder of the linear aspect of the process. What is more difficult to remember

is the cyclic aspect of the process. Even the most basic activated sludge

process has a sludge recycle (see Figure 1).

FIGURE 1

The purpose of any

recycle is to return a portion of the waste stream from one part of the process

to another part of the process. The return sludge in a conventional activated

sludge process ensures that the settled biomass is recycled back to the head of

the aeration basin. Without this recycle, the aeration basin would never

develop a large enough biomass to remove the substrate (BOD, phosphorous or

nitrogen).

Interestingly, the most basic BNR

process, and one of the first activated sludge processes developed early on,

did not have any recycle. That process is the Sequencing Batch Reactor (SBR).

In the BNR mode, wastewater enters the tank at the beginning of the process

(Mix/Fill) while the MLSS is in an anaerobic condition, then aeration begins

(React/Fill) placing the MLSS in an aerobic condition, after which the filling

stops (React On/Off). When the MLSS is almost fully oxidized the next two phases

of the SBR process begins (Settle), and finally (Decant/Idle). The MLSS is in an

anoxic condition at this point. Then the process starts over again. Since it is

a batch process and everything proceeds sequentially in a single tank, there is

no need for recycle (Figure 2).

FIGURE 2

The beauty of the SBR process is the BNR process follows the logical sequence required by nature. For this reason, it is the perfect place to begin learning about the BNR process. Figure 3 illustrates the basic stages of the BNR process. The anaerobic section (Mix/Fill) of the SBR process is Stage One of the luxury phosphorous uptake process. The aerobic section (React/Fill & React) of the SBR represent Stage Two of the luxury phosphorous uptake process and Stage One of the Nitrogen Removal Process (Nitrification). The anoxic (Settling and Decant) sections represent Stage Two of the Nitrogen Removal Process (Denitrification). Carbonaceous BOD removal occurs throughout the whole SBR process.FIGURE 3

Included in Figure 3 is a secret

that many operators are not aware of. Optimum BNR occurs only if the wastewater

remains in each of the three major respiratory modes (anaerobic, aerobic and

anoxic) long enough to complete the process. If the Mix/Fill phase is not long

enough, the first stage of the luxury phosphorous uptake process (phosphorous

release) will not be complete. The same is true for stage two of the luxury

phosphorous uptake process (phosphorous uptake), nitrification, and

denitrification. The percentages located below the three respiration modes

represent the relative amount of the total treatment time required for that

particular mode. For example, stage one of luxury phosphorous uptake requires

somewhere between 15 to 20% of the total treatment time in the SBR process.

Another way to visualize it is represented in Figure 4.

FIGURE 4

Why is this important?

When SBRs have difficulty with

phosphorous, ammonia or nitrate removal, in many cases it is due to a

deficiency in treatment time in one of the three respiration modes. An increase

in effluent phosphorous can often be traced back to either 1) not enough time

in the anaerobic mode or 2) not enough time in the anoxic mode. 1) can be

corrected by lengthening the Mix/Fill phase. 2) results in incomplete

denitrification during the Settling/Decant phase which allows nitrates to enter

the Mix/Fill phase of the SBR process which is supposed to be “anaerobic.” The

reason for the quotes is, as we all know, “anaerobic” is defined as “zero DO,

zero nitrates”. If nitrates are in the “anaerobic” phase of the process, that

phase is not anaerobic, but anoxic, no matter what we may call it. In the

second scenario either a) the settle/decant phase is not long enough, b) the DO

is too high at the end of the aerobic (react) phase, or c) the (React) phase is

too long.

Just remember that when making

changes to the time of any one of the phases it will affect the times of the

other phases as well.

What Happens in Each of the

Three Respiration Modes?

Figure 5 illustrates the relative

concentrations of BOD, phosphorous, ammonia, nitrate/nitrite and alkalinity

levels during the anaerobic, aerobic and anoxic modes.

FIGURE 5 Relative Nutrient Concentration During the BNR Process

Under normal conditions the

phosphate concentration goes up during this period, often as much as four times

the influent concentration. During the aerobic period of the process the PAOs will

take up as much as seven times the amount of PO4 they originally released. The PO4

concentrations at the end of the anaerobic period should be below 0.5 mg/L. Tracking

the PO4 concentrations at the influent and effluent end of the anaerobic

period is a good indicator of the health and effectiveness of the PAOs.

Nitrogen is found in the influent

in two primary forms; approximately 40% is in the form of ammonia (NH3)

and approximately 60% is in the form of complex organic nitrogen measured as

Total Kjeldahl Nitrogen (TKN). The TKN portion of the nitrogen is converted to

ammonia during the anaerobic and aerobic periods of the BNR process. Thus, if

just ammonia is measured in the influent at a concentration of 12 mg/L, the

amount of TKN could be around 30 mg/L. The actual ammonia that would have to be

converted is around 40 – 45 mg/L. This is reflected by the rising yellow line during

the aerobic period.

During the aerobic period the

nitrifiers are actively converting ammonia to nitrite/nitrate (NOX).

This is represented by the falling yellow line (NH3) and rising

purple line (NOX) during the aerobic period. By the end of that

period the NH3 should be well below 1.0 mg/L and the NOX

should be in the 30 – 40 mg/L range.

During the anoxic period of

treatment, nitrate/nitrite (NOX) will be converted to nitrogen gas

(Ná). It is important that as much (NOX)

be converted to (Ná)

as possible before the process is returned to the “anaerobic” period of

treatment. Any (NOX) entering the “anaerobic” period shortens that

period. Remember, (NOX)’s in the MLSS means it is still anoxic.

If the BNR process is working

properly, the alkalinity (and eventually the pH) will decline during the

aerobic period due to the nitrifying organisms (remember they are autotrophic –

they consume inorganic carbon such as carbonate). During the anoxic phase, however,

the denitrifying bacteria will recover approximately 50% of the original

alkalinity.

Process Control

So, based on the above discussion,

it should be pretty obvious what process control samples need to be pulled and

where. Figure 6 illustrates the process control samples that should be pulled

for optimizing and monitoring the process. The picture includes a clarifier and

internal recycle for a system that is not an SBR, but the principles are the same.

FIGURE 6 Putting It All Together

The primary different between sampling

and testing for process control and troubleshooting is frequency. When

everything is working well the amount of sampling can be greatly curtailed.

However, if the system is experiencing problems, the type and severity of

problem, will dictate the location, frequency and duration of the sampling and

testing. For example, it is not necessary to test for ammonia if the system is experiencing

elevated PO4 values.

Feel free to contact me should

you serve a population >10,000 or have any questions or issues that the GRWA

is unable to assist you with. Also, if you would like to contribute an article

feel free to email me at the address below. I am always looking for

contributors that have an interesting perspective, topic or has an interesting

case that they would like to share – especially if the solution is a direct

result of applying the principles from this forum.

Dennis Brown,

Wastewater Specialist and Trainer, Retired

678.750.3996

Comments

Post a Comment