Biological Nutrient Removal Basics

II

The goal of this article is:

1. To

discuss the purpose of recycle in configurations other than SBRs.

2. To

review inhibiting BNR processes.

Learn Theory! Learn Theory! Learn Theory! If you know

theory you can use it! If you don’t know theory you can’t use it! (Extraordinary

Leadership: Thinking Systems, Making a Difference, 2009, Reberta M. Gilbert,

M.D, pg 5)

____________________________________________________________________________________

The last article discussed some

basic BNR concepts as it relates to sequencing batch reactors. This article

will cover how these concepts can be applied to configurations other than SBR’s.

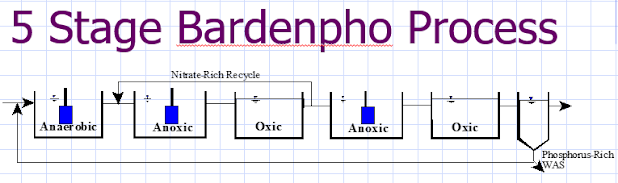

Figure 1 below illustrates the configuration of a 5-Stage Bardenpho Process.

FIGURE 1 The 5-Stage Bardenpho

Process

Recycle

The primary difference between an

SBR and more conventional configurations is the SBR is divided TIME while

other treatment configurations are divided by SPACE. In other words, in facilities

other than SBR’s, the anaerobic, aerobic and anoxic periods are processed in

separate tanks. These tanks are fixed in size, which means the amount of time

the wastewater spends in each tank is determined by the flow entering that tank

(hydraulic detention time). The only ways the hydraulic detention time can be

altered is by changes in the influent flow, or the addition of internal

recycle. In the illustration above, there are two internal recycles: one to

return nitrate-rich wastewater from the effluent of the aerated tank to the influent

of the first anoxic tank. The second one returns the MLSS from the final

clarifier to the head of the anaerobic tank. One recycle that is not shown that

has become more common is a recycle line to return phosphate-rich wastewater from

the aerobic tank back to the anaerobic tank for additional processing.

The recycle rates in conventional

activated plants (plants not required to nitrify or remove any other nutrients)

are typically in the range of 50% - 150% of the average daily flow. In BNR

systems, the recycle rates can be as high as 600% (a six to one ratio) of the

average daily flow. The primary purpose of the internal recycle is to return

partially processed wastewater back to the previous tank for additional

processing. The way recycle does this is by increasing the hydraulic retention

time in that specific portion of the process. To express it in another way, using

the illustration in figure 1 above as the example, when flow is returned from

the effluent end of the oxic tank to the anoxic tank, the hydraulic retention

time is increased in those two tanks, and in those two tanks only.

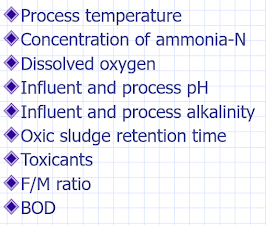

Typical Factors Inhibiting

Biological Nutrient Removal

Besides ensuring there is enough

time for the separate BPR processes to be completed, there are other factors

that can inhibit BPR. The most common factors are expounded on below.

Factors Inhibiting

Nitrification

Nitrification consumes

approximately 7.1 parts of alkalinity for every part of ammonia converted to

nitrate. It also consumes around 4.6 parts of oxygen for every part of nitrate

produced. Concerning oxygen, oxidation ditches have been known to fully nitrify

at DO levels of 0.7 mg/L, so it is not necessary to jack up the oxygen levels above

1.0 mg/L when having ammonia issues. The optimum pH range is 7.5 to 9.0 units,

but they do not like sudden changes in pH. The effluent alkalinity should be

maintained at 70 mg/L but not allowed to drop below 40 mg/L for long periods.

The BOD:TKN ration should be above 4:1 and the SRT should not be allowed to drop

below five (5) days.

If accepting leachate, leachate tends

to produce a tan color in the effluent. This color can interfere with the colorimetric

test method for ammonia (anything using a spectrophotometer), so the

electrometric test method (probe) is recommended instead.

Factors Inhibiting

Denitrification

The definition of anoxic for

wastewater treatment is MLSS with ‘No Free Oxygen and Some Nitrates’. For

optimum denitrification, a DO level well below 0.4 mg/L is required. Because denitrification

always follows nitrification, the endogenous BOD may be depleted prior to the nitrated

reaching the anoxic period of treatment. There needs to be at least 2.9 parts

of COD (BOD takes too long to analyze) for every part of nitrate and the proper

range for the other environmental factors (pH, temp, SRT). For every 1.0 part

of NOx converted to Nitrogen gas, 3.6 parts of alkalinity will be recovered, reducing

the need for alkalinity addition.

One condition that can occur is

oxygen creep from the aerobic phase or tank into the anoxic phase or tank, especially

during winter when the oxygen saturation rate of the water is very high, microbial

activity is very low and/or the DO levels in the aerobic tank are very high. Oxygen

can carry over into the anoxic tank converting it into an aerobic tank.

Concerning DO Levels, practically

speaking for both optimum treatment performance and power consumption, the DO

should be kept as low as possible in the aerobic portion of treatment. Generally

speaking, unless there is something else going on in the aeration basin, the DO

does not have to exceed 1.0 mg/L in non-SBR systems and in SBR systems the

maximum optimum DO may fall between 1.5 – 2.5 mg/L . This will almost ensure

that oxygen creep into the anoxic period of treatment will not occur.

Factors Inhibiting Luxury

Phosphorous Uptake

The definition of anaerobic for

wastewater treatment is MLSS with ‘No Free Oxygen and No Nitrates’. Facultative

organisms will utilize oxygen from various molecules in the following order: O2,

NO3, SO4 and CO2. There is normally very

little SO4 and CO2 in the waste stream, therefore

tracking the NO3 levels entering the “anaerobic” period of treatment

is sufficient to ensure the system is truly in an anaerobic condition.

Concerning NOx in the influent, the

NOx concentrations are typically well below 1.0 mg/L. However, there is a

popular chemical often added to the collection system for odor control. This chemical

is Calcium Nitrate. It does a good job of reducing or eliminating sulfide

production in the collection system but will ‘poison’ a biological phosphorous

removal (BPR) process. Additionally, Nitrate/Nitrite or total nitrogen limits

are being added to NPDES permits and adding calcium nitrate may have an adverse

effect on the effluent stream as well.

Side Stream Management. Plants

just beginning biological phosphorous removal have never had to be concerned

with high phosphorous levels in the digester decant. The phosphorous that has

been absorbed by the biosolids will be released again when the air is turned off

for decant. If left off for more than 24 hours, the phosphorous in the decant can

exceed 700 mg/L. This will be returned to the head of the plant and will have

an impact on the effluent phosphorous levels.

Plants that are monitoring

phosphorous may want to consider operating the digester in a manner that

reduces the amount of phosphorous discharged back to the head of the plant. The

main objective would be to decant a little every day. One method would be to

only aerate the digester for three hours immediately after decanting, then

turning the air off, letting it settle overnight, then decant first thing in

the morning. This would have to be done every day.

Conclusion

These are just some of the more typical

issues that can affect nutrient removal in the typical WWTP. Paying attention

to these factors can serve as signposts for process control and can assist in

the ability to troubleshoot the plant. There are may other factors that may

occur as well.

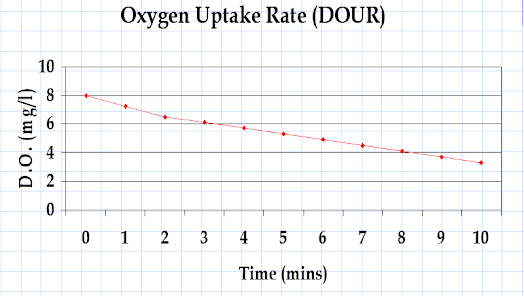

The next article will focus on what

I call “The Fifteen Minute BOD” and the

University of Tennessee says is the “most valuable yet underutilized test

available for operators of the activated sludge process”.

The Georgia Rural Water Association is

always available to assist any municipality that serves a population of

<10,000 with process control, troubleshooting, training, lift station

maintenance, smoke testing, leak detection, standard operating procedure

development, asset management development, or any other compliance and

operational issues that may crop up. To request their assistance, please

contact them at Contact Us -

Georgia Rural Water Association (grwa.org).

***********************************************************************************

Feel free to contact me should

you serve a population >10,000 or have any questions or issues that the GRWA

is unable to assist you with. Also, if you would like to contribute an article

feel free to email me at the address below. I am always looking for

contributors that have an interesting perspective, topic or has an interesting

case that they would like to share – especially if the solution is a direct

result of applying the principles from this forum.

Dennis Brown,

Wastewater Specialist and Trainer, Retired

678.750.3996

Comments

Post a Comment